About Stainless Steel Wire Braid

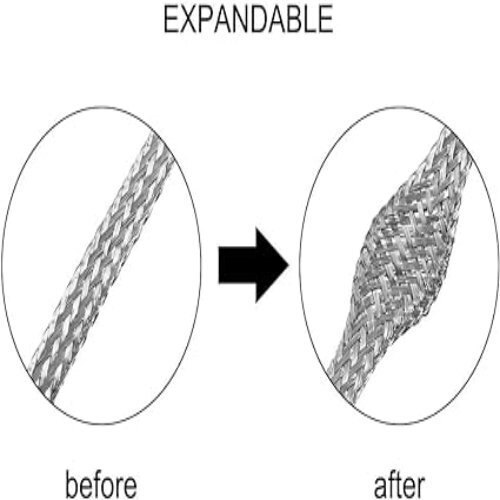

The stainless steel flexible hose is covered with an external braiding made from stainless steel wire. The wire braiding can be either single or double layer according to pressure rating required. Braiding increases the hoop strength, stabilizes movement and offers a form of protection to inner corrugated tubing We have, Indias first and only 124 carrier wire braiding machine.

Superior Performance for Demanding ApplicationsOur stainless steel wire braid hoses guarantee reliable performance in even the harshest environments. Engineered for flexibility, they absorb vibrations, accommodate movement, and withstand high temperatures and pressures, making them essential for industrial, hydraulic, gas, steam, and chemical operations. The polished finish and superior corrosion resistance promote longevity, even under continuous exposure to harsh media.

Versatile Construction and CustomizationChoose from single or double braid configurations in a size range of 1/8 inch to 12 inch. Each hose features a robust stainless steel tube and a polished wire braid cover, offering excellent mechanical strength and flexibility. Available in rolls or tailored to your specified length with flanged, threaded, or welded connections to suit any installation needs.

FAQs of Stainless Steel Wire Braid:

Q: How does the stainless steel wire braid improve hose durability?

A: The stainless steel wire braid acts as a reinforcement layer, protecting the hose from external damage and enhancing its ability to withstand high pressure and temperature. This design ensures greater longevity and maintains flexibility, even in demanding industrial conditions.

Q: What applications are suitable for these wire braided hoses?

A: These hoses are versatile, making them ideal for industrial, hydraulic, gas, steam, and chemical systems. They are specifically engineered for flexible connections and vibration absorption, handling media such as air, water, oil, steam, and various chemicals.

Q: When should I opt for a double braid instead of a single braid?

A: A double braid is preferred when higher working pressure or additional strength is required. It is ideal for situations where the hose will be exposed to more demanding pressures, frequent movement, or harsher environmental conditions.

Q: Where can these stainless steel braided hoses be installed?

A: They are suitable for installation in factories, petrochemical plants, refineries, or other industrial sites where reliable and flexible piping is essential for safety and performance. The hoses can be customized with various connection types to fit different system designs.

Q: What is the process for ordering customized hoses?

A: To order customized hoses, specify your required length (up to 50 meters), connection type (flanged, threaded, or welded), and any specific braid construction needed. Orders are typically packaged in rolls or as per customer instructions, ensuring prompt and accurate delivery.

Q: What are the main benefits of using polished stainless steel with a wire braid cover?

A: The polished stainless steel with wire braid cover offers exceptional corrosion resistance, flexibility, and mechanical strength. This results in efficient performance, reduced maintenance, and longer service life, even under extreme temperature and pressure ranges.